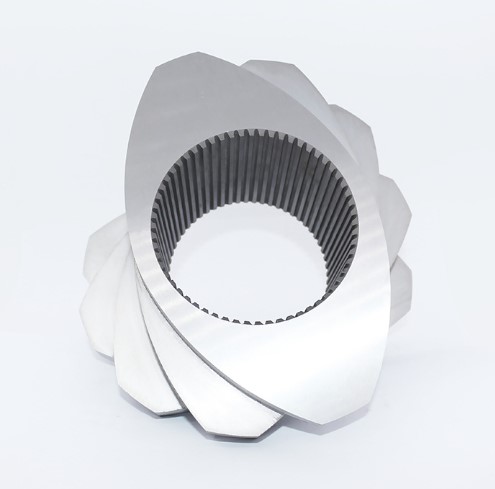

Shearing elements

Kneading blocks

Shearing element (kneading block)

Mechanism of action: By generating high shear force through staggered angles (30°, 45°, 60°, 90°), it achieves the dispersion and mixing (crushing of particles) and

distribution and mixing (component exchange) of materials.

Performance

The misalignment Angle ↑ → distributed mixing ↑, but the optimal dispersed mixing is achieved at 45°

Thickness ↑ → shear force ↑, but uniformity of mixing ↓

Application scenarios: Melting section pressurization, mixing section enhanced dispersion (such as glass fiber or carbon black filling)

Mixing element (TME)Grooves are made on the screw ribs (straight teeth/helical teeth), connecting adjacent screw grooves to facilitate longitudinal exchange

.

Advantages: High shear rate + low building pressure capacity, suitable for distributed mixing (such as color masterbatch dispersion or low-viscosity additive blending)

Material and durability

High-speed tool steel (W6Mo5Cr4V2) : Economical and universal;

Nitrided steel (38CrMoAlA) : Corrosion-resistant;

High-performance alloys: tungsten carbide (WC) alloy (with wear resistance increased by 7-8 times), Wr5 powder alloy (mainstream in Europe and America, with wear

resistance increased by 4-5 times),

suitable for highly abrasive fillers (such as glass fiber or minerals)

Process technology: Hot isostatic pressing (HIP) molding → Enhancing density and lifespan